Benefits:

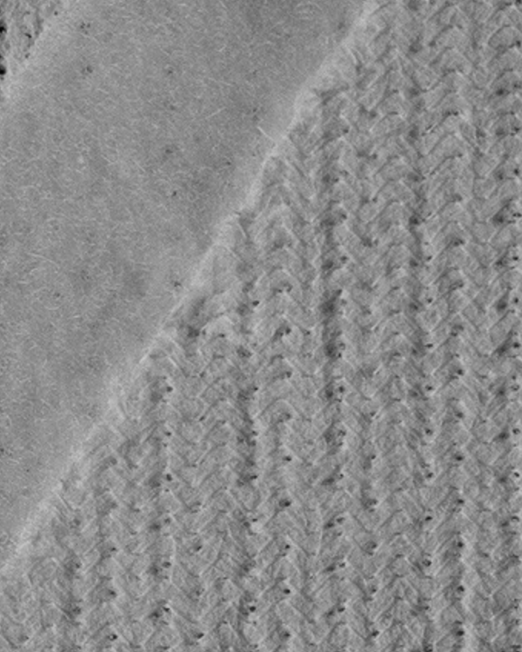

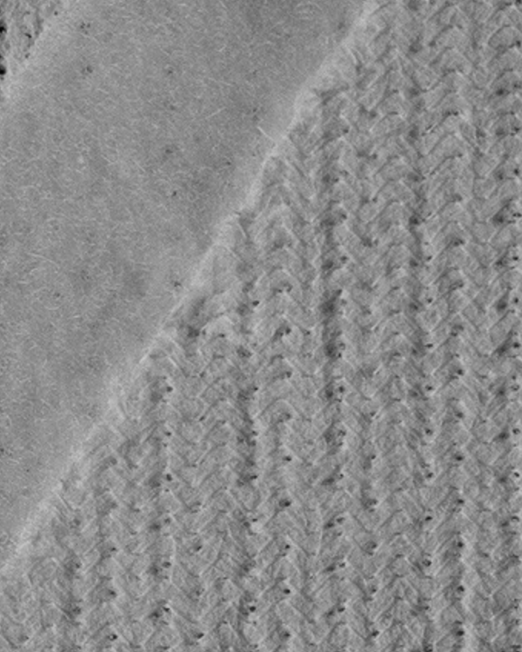

- Alkali resistant fiberglass;

- Safe easy handling

- Excellent mechanical performance

- Easy blending into the GRC matrix

- Easy spraying & chopping

- Perfect for incorporation into complicated composite profiles and details

- Been approved by Sheffied University,UK

Dosage:

AR Glassfibre roving’s are used for spraying with industry standard GRC spray equipment. The normal recommended dosage is 5% by weight.

Packaging & Storage:

18±1kg/roll,individually shrunk film packaging (with weight tag);Each fumigated pallet has 3 or 4 levels with 16 rolls/ level,48 rolls/small pallet , 64rolls/big pallet.

It loads 20 pallets (Small & big pallet stacked in 2 layers) per 20 feet container, with a net weight 20tons.

AR Glassfibre roving pallet shall be stored dry in original packaging and advisable to stack in one layer, at a temperature between 15℃- 35℃ & relative humidity between 35%- 65%.If stored below 15℃, it is advisable to hold in workshop for 24 hours to prevent condensation before use.