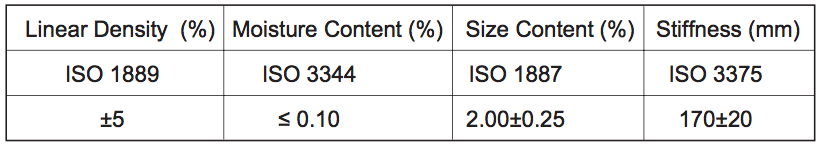

Technical Parameters

Storage

Storage

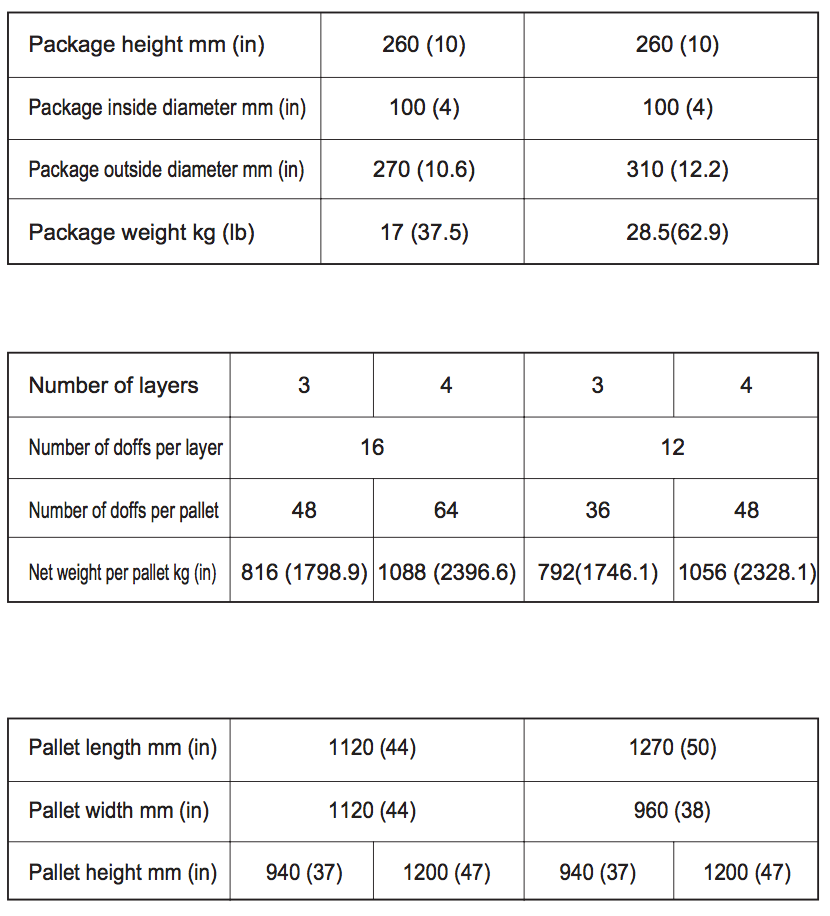

Unless otherwise specified, fiberglass products should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15C ~35C and 35% ~65% respectively. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high. When the pallets are stacked in 2 or 3 layers, care should be taken to correctly and smoothly move the top pallet.

Packaging

* The product can be packed on pallet or in small cardboard boxes.

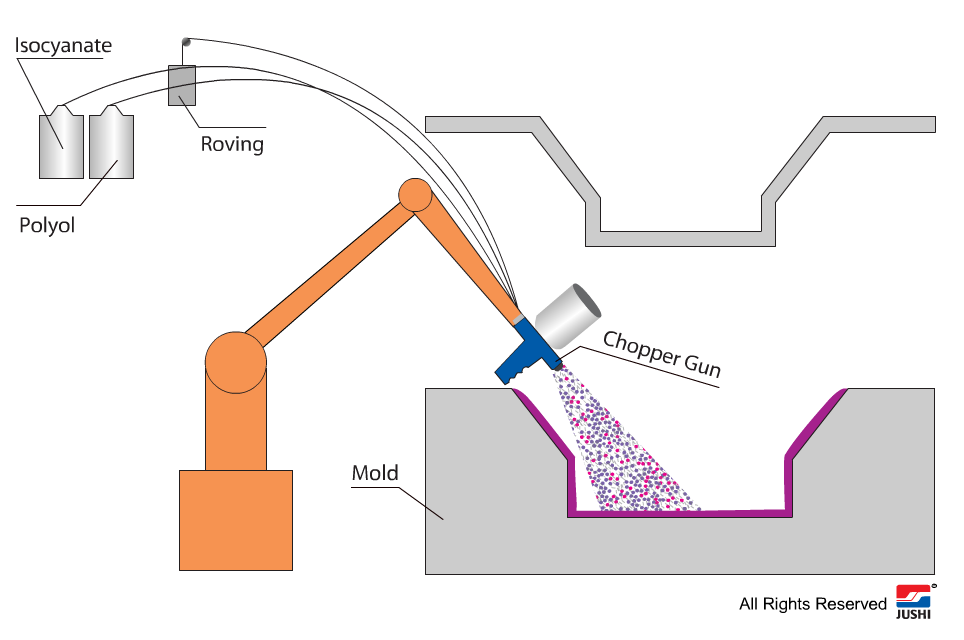

Long Fiber Injection Process (PU-LFI)