Technical Parameters

Storage

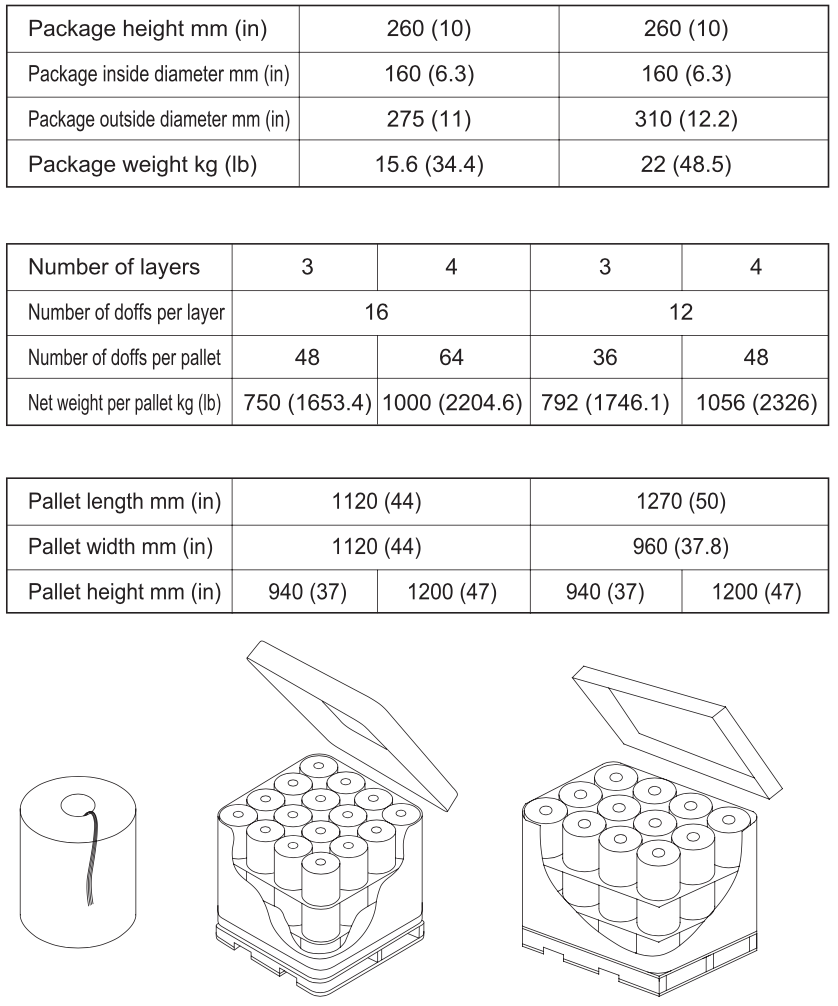

Unless otherwise specified, the fiberglass products should be stored in a dry, cool and moisture-proof area. The room temperature and humidity should be always maintained at 15 C ~ 35 C and 35% ~65%. It is best if the product is used within 12 months after production date. The fiberglass products should remain in their original packaging until just prior to user.

To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high. When the pallets are stacked in 2 or 3 layers, special care should be taken to correctly and smoothly move the top pallet.

Packaging

*The product can be packed on pallet or in small cardboards boxes.

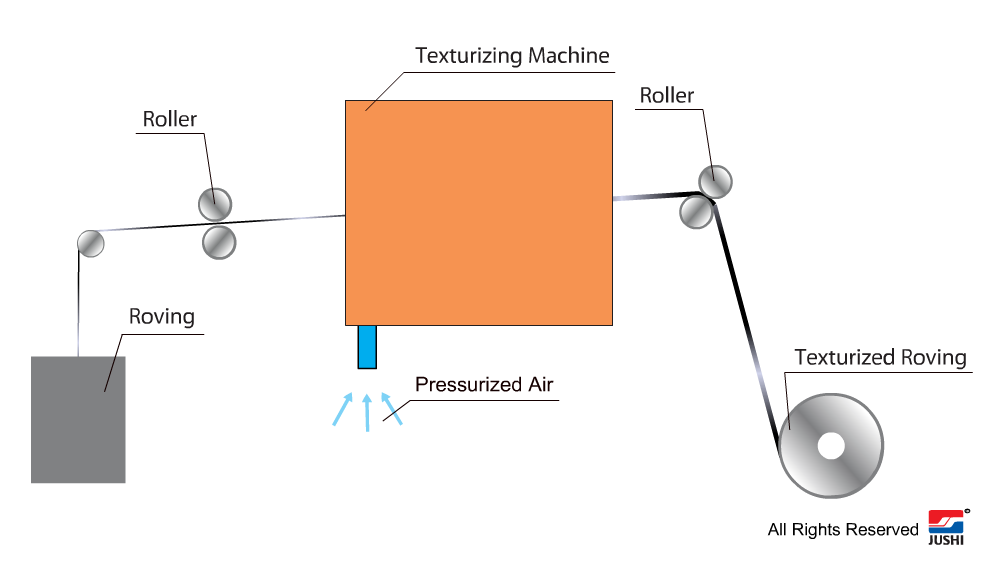

Texturizing

Texturizing is a process in which a fiberglass roving (or a yarn) is subjected to an air jet that impinges on its surface to make the roving “fluffy”. The air jet causes the surface fibers to break at random, giving the roving a bulkier appearance. The extent to which this occurs can be controlled by the velocity of the air jet and the roving feed rate. The texturizing process allows the resin-to-glass ratio to be increased in the final composite part. End use applications include: fabric for welding curtains, stress-relieving blanket, compression gasketing, friction material, muffler filling and pipe insulation.