PRODUCT PROPERTIES AND RANGE OF APPLICATION

Description of the Products:

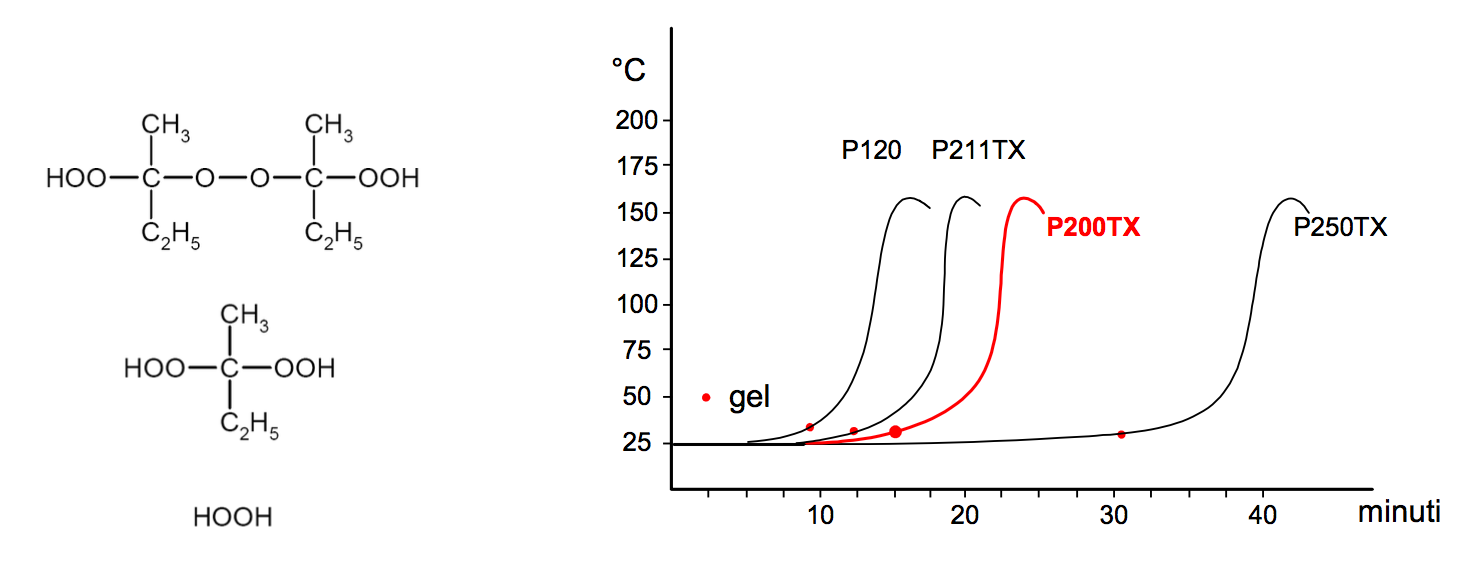

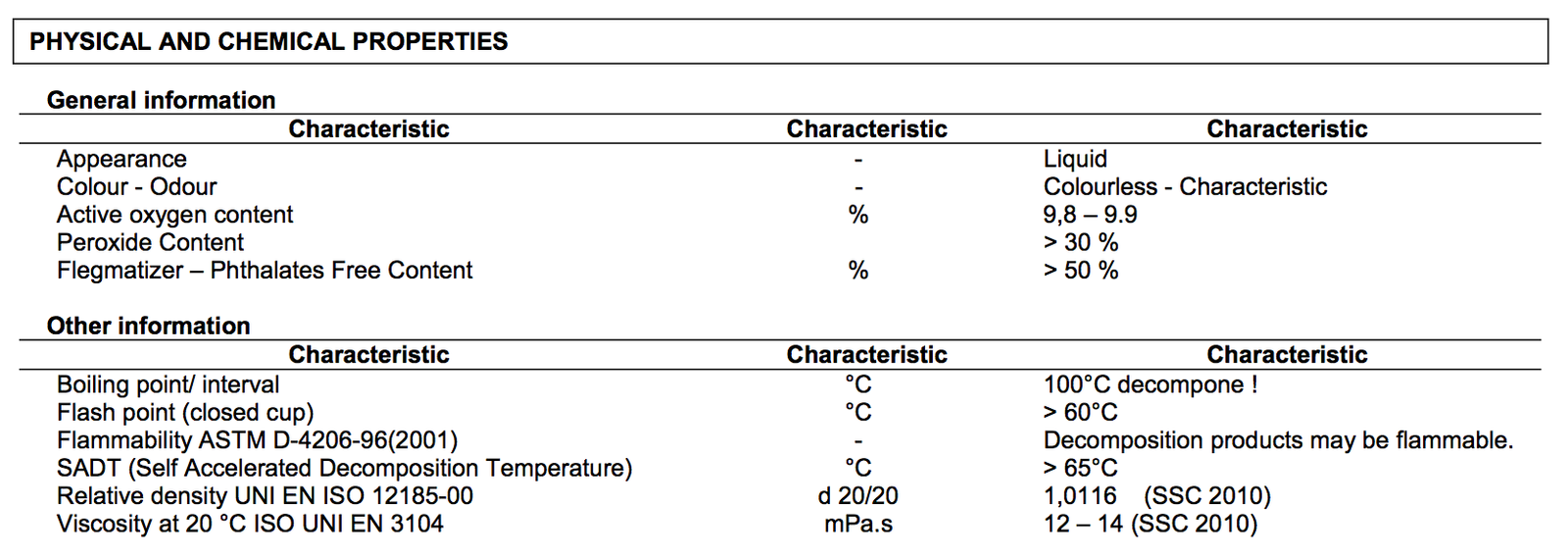

The PROMOX P211TX is a new formulation of MethylEthylketone peroxide (CAS 1338-23-4) solution in plasticizers, Phthalates free. It is used for the curing process of unsaturated polyester resins together with various accelerating systems.

The PROMOX P211TX is new and innovative formulation Phthalates free. The new flegmatizers employed for this kind of formulations are totally safe. Due to that users will not have further risks during the manipulation, use and disposal of this solution. The PROMOX P211TX is formulated with 2,2,4-trimethyl-1,3-pentanediol diisobutyrate as flegmatizer. It is a colourless liquid with very low vapor pressure that does not evaporate appreciably at room temperature. This additive is ideally suited for phthalates-free applications.

Accelerators and Promoters:

The PROMOX P211TX is used in most production cycles at temperature ranging from 15 to 80 degrees centigrade. The concentration of use generally ranges from 1 to 2 part /100 parts of resin. Generally cobalt salts (octoate, naphtenate) are used but seldom vanadium o manganese salts. The accelerator performances can be improved by adding promoters which exalt their action.

Uses and Contraindications:

PROMOX P211TX is a peroxide for general uses with a high-range cross-linking activity. It is a peroxide for general uses, with a low content in not reacted raw materials. It is particularly useful for the curing of orthophtalic and polyester resins while it is advisable to use it neither with isophtalic, bisphenolic, vinilesters resins nor with the gel coats.

It’s a general purpose MEKP with Medium reactivity. Application sectors: Polyester resins, Gel & Top Coats, Bonding Pastes. At Ambient temperature: Hand lay-up and Spray lay-up, RTM technologies, Cold press moulding, Buttons, Vacuum bag or Infusion, Polyester concrete and Marble. At Elevated temperature: Continuous Lamination, Filament Winding, Centrifugal Casting.

Packaging:

Promox peroxides are normally packaged in 25 kg polyethylene drums. Smaller packaging is available as requested. Drums are palletised from 600 to 900 Kg weight net.

Stability:

The product is stable under normal storage conditions for at least six months from the date of production.

Storage:

When the product is stored under recommended storage conditions, it keeps the original properties for a period of at least six months after delivery. Recommended storage Temperature: < 30°C.