PRODUCT PROPERTIES AND RANGE OF APPLICATION

Description of the Products: The PROMOX P401 peroxide is a solution of CycloHexanone peroxide (CAS 12262-58-7) in plasticizers. It is used for the curing process of unsaturated polyester resins together with various accelerating systems.

The PROMOX P401 is used in most production cycles at a temperature ranging from 15 to 80 degrees centigrade. The PROMOX P401, in the presence of a cobalt accelerator, may be used at room and elevated temperatures. The concentration of use generally ranges from 1 to 2 part /100 parts of resin.

Accelerators and Promoters: Generally cobalt salts (octoate, naphtenate) are used but seldom vanadium o manganese salts. The accelerator performances can be improved by adding promoters which exalt their action.

Uses and Contraindications: The PROMOX P401 is an high activity peroxide which assures a quite short gel time, a fairly rapid hardening, but gradual and regular, with a low exothermic peak. This kind of behaviour gives, as final result, less colour variations of the resin and so of the final article. Such type of peroxide, additionally, ensures a optimum hardening of reduced thickness artefacts without causing mechanical stress areas and/or creation of ruptures and/or cracks. Together with suitable resins is employed for the production of slabs that both buttons from rods. Is also used for the curing of large compounds, in paint catalysis at ambient temperature together with a cobalt accelerator.

The PROMOX P401 is an high activity cross linking peroxide formulated for specific applications. Application sectors: Polyester Resins. At ambient temperature: Hand lay-up and Spray lay-up, Buttons.

Packaging: Promox peroxides are normally packaged in 25 kg polyethylene drums. Smaller packaging is available as requested. Drums are palletised from 600 to 900 Kg weight net.

Stability: The product is stable under normal storage conditions for at least six months from the date of production.

Storage: When the product is stored under recommended storage conditions, it keeps the original properties for a period of at least six months after delivery. Recommended storage Temperature: < 30°C.

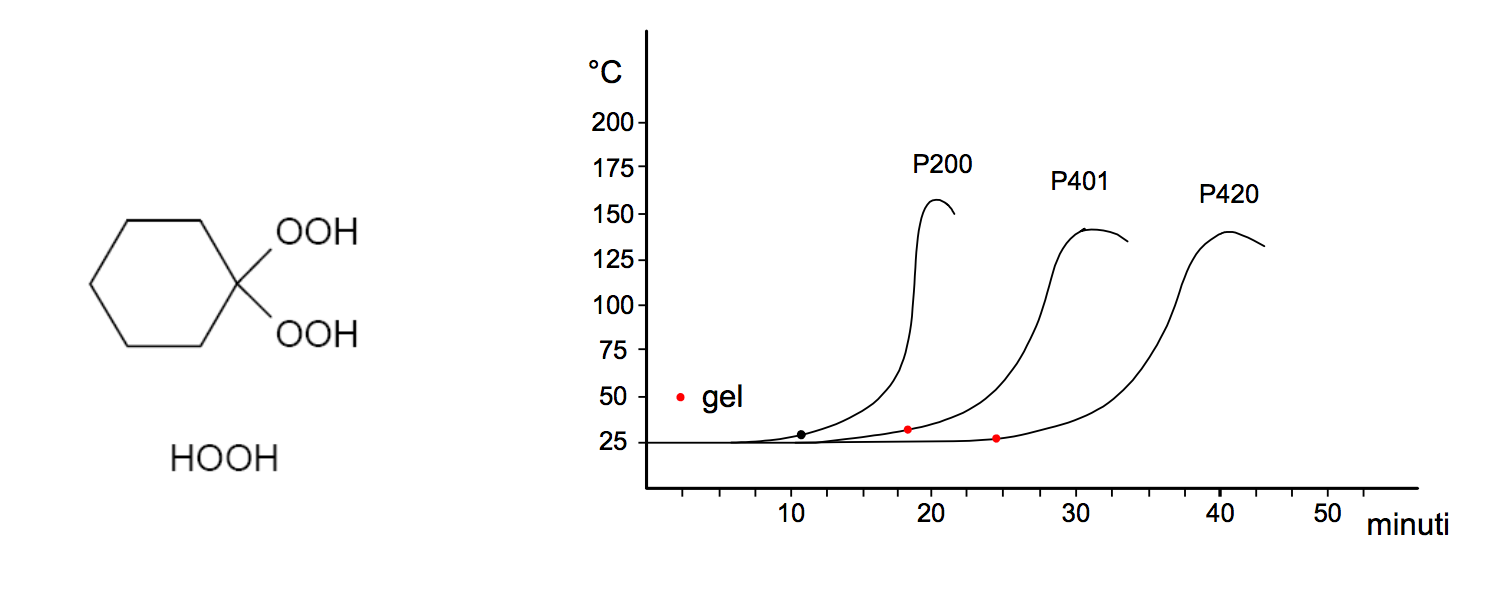

Curing Diagrams: The following diagram helps the users to choose the most suitable Promox product. It compares the activity of Promox P401, P401 with a normal MekP. A medium reactivity, preaccelerated orthophtalic resin has been used to test the peroxide. The curves were obtained by adding 2 parts of peroxide /100 parts of resin at 25° C.