Technical Parameters

Mechanical Properties

The above data are actual experimental values for EDR24-2400-386 and for reference only.

Storage

Unless otherwise specified, fiberglass product should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15C ~35C and 35%~65% respectively. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high. When the pallets are stacked in 2 or 3 layers, care should be taken to correctly and smoothly move the top pallet.

Packaging

*The product can be packed on pallet or in small cardboard boxes.

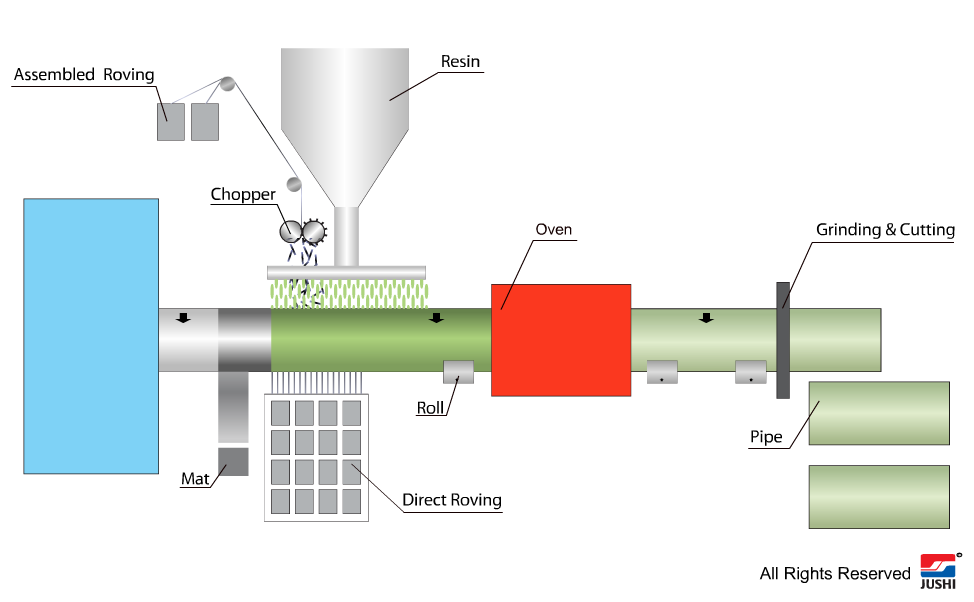

Continuous Filament Winding Process

Continuous Filament winding is an open molding process that uses a rotating “disappearing” mandrel, which is formed from a continuous steel band continuously traveling in a cork-screw motion around the spacer bars and returning through the center after de-molding. Successive stations are used to form layers of varying composition. Both chopped and continuous rovings are used. The part is heated and cured in place as it travels through the line and is cut into a specific length with a traveling cut-off saw. This process is limited to large diameter pipes or cylinder walls. The diameter is infinitely adjustable.

Continuous Filament winding is an open molding process that uses a rotating “disappearing” mandrel, which is formed from a continuous steel band continuously traveling in a cork-screw motion around the spacer bars and returning through the center after de-molding. Successive stations are used to form layers of varying composition. Both chopped and continuous rovings are used. The part is heated and cured in place as it travels through the line and is cut into a specific length with a traveling cut-off saw. This process is limited to large diameter pipes or cylinder walls. The diameter is infinitely adjustable.