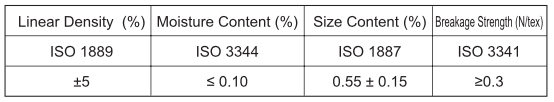

Technical Parameters

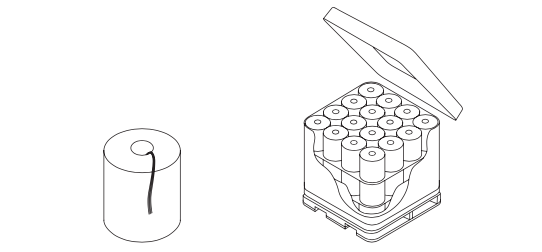

Storage

Packaging

*The product can be packed on pallet or in small cardboard boxes.

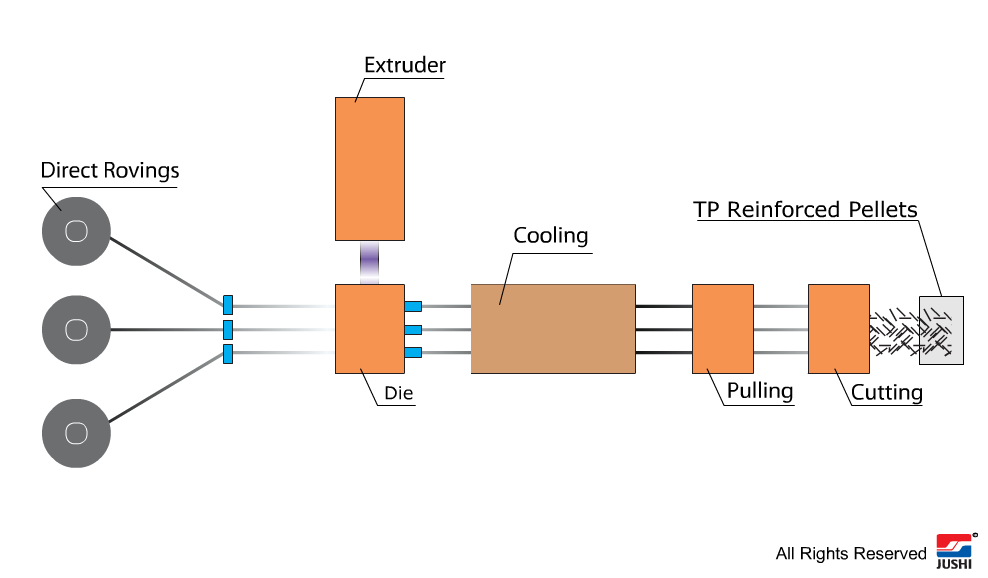

LFT-G (or LGT-P) Process

In the LFT-G (or LGT-P) process, the resin is heated together with additives to a molten phase and pumped to the die-head. The continuous roving is pulled through dispersion die, ensuring good impregnation of the glass fibers by molten polymer and consolidation into a rod. After cooling, the rod is chopped into reinforced pellets of 12-25 mm length. The end-users can use injection or compression molding to make final parts with well defined properties.

In the LFT-G (or LGT-P) process, the resin is heated together with additives to a molten phase and pumped to the die-head. The continuous roving is pulled through dispersion die, ensuring good impregnation of the glass fibers by molten polymer and consolidation into a rod. After cooling, the rod is chopped into reinforced pellets of 12-25 mm length. The end-users can use injection or compression molding to make final parts with well defined properties.