Technical Parameters

Storage

Unless otherwise specified, fiberglass products should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15C ~35C and 35% ~65% respectively. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high. When the pallets are stacked in 2 or 3 layers, care should be taken to correctly and smoothly move the top pallet.

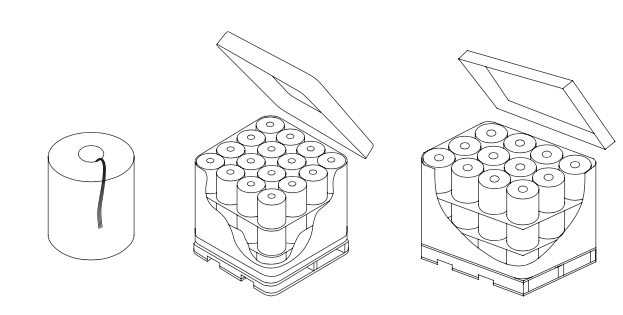

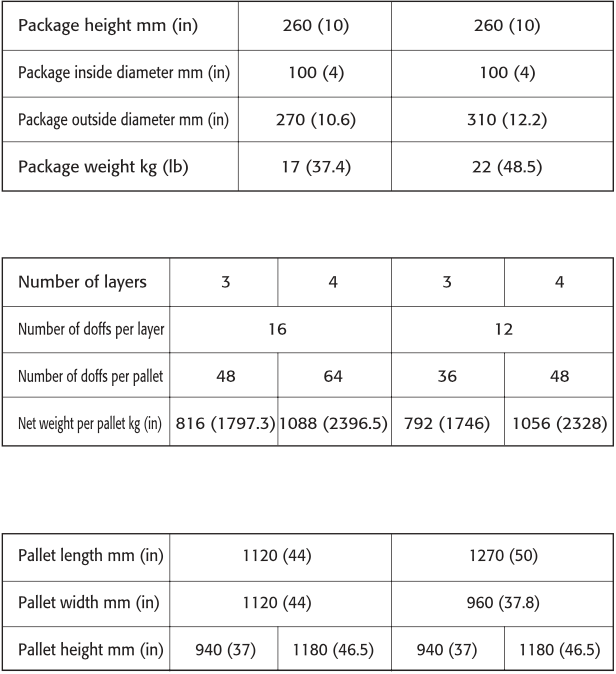

Packaging

* The product can be packed on pallet or in small cardboard boxes.

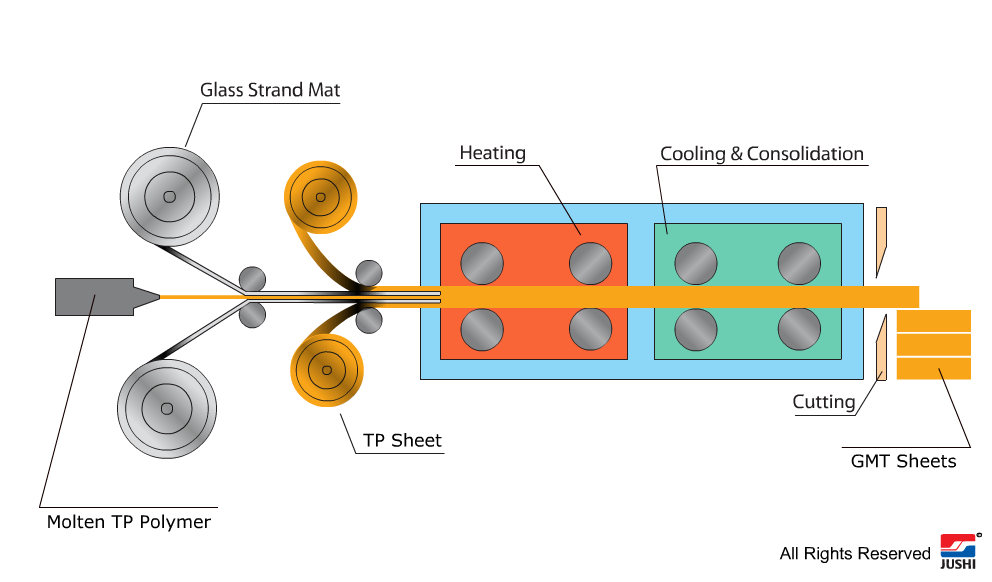

Glass Mat Reinforced Thermoplastics(GMT) Process

GMT (Glass Mat Thermoplastic) is a multi-step process. First, a needled mat is used or a mat is formed in-situ by chopping assembled roving. Then, one or two layers of reinforcing mat are sandwiched between two or three sheets of polypropylene. This sandwich is then heated and consolidates into a semi-finished sheet product. The GMT sheets are then heated and molded using stamping or compression process to make complex finished parts.